Project Coordinator: Asst. Prof. Ozan KEYSAN

Project Type: TUBITAK 1001 Scientific and Technological Research Projects Funding Program

Project Budget: 380.000 TL

Project Duration: 24 months

Project Start Date: 01 November 2019

Funded Personnel: 3 MSc Students (Full-Time)

In small power applications inductive wireless power transfer has been used in the consumer electronics and for high power applications (>1kW) many research outputs are presented especially in wireless electric vehicle charger. Other uses of contactless slip rings are the rotating systems of radar-guidance systems, pitch angle adjuster servo motors in wind turbines and field excitation slip rings. Although brushless exciters are used for field excitation of electrical machines (high power applications) these units have narrow operating speed range and they are not efficient. In the industry, contactless slip rings are produced by a few companies. However they require separate shafts and mounting. Moreover, these systems have single transmitter and receiver modules therefore their fault tolerances are low.

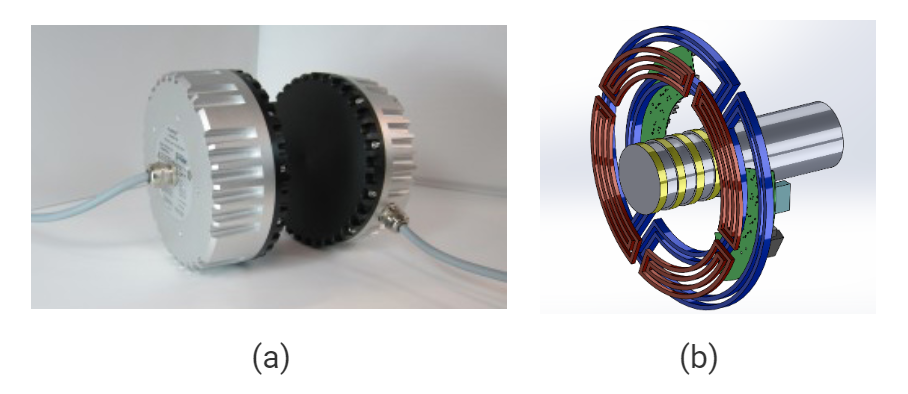

Modular structure: Using multi transmitter and multi receiver it is aimed to increase the tolerance to fault conditions and increase the operating speed range. In the case of a fault in single transmitter and receiver the unit need replacement whereas in the modular case like in Figure 1.b only the fault modüle needs replacement. Moreover with modular units the product can be mounted on a single shaft where in the case of Figure 1.a two seperate shafts are required. Series-series resonant converter: Using series-series resonant converter the overall system efficiency is aimed to be kept >90% for all conditions. Silicon Carbide (SiC): SiC have low switching losses and allows higher power to be switched. Hence it is thought to give the Project flexibility. Moreover SİC systems have much higher efficiency then Si MOSFET and Si IGBTs. Also they can operate at higher temperatures.

The proposed project is about a contactless, modular slip ring alternative system which has wide operating speed range, high efficiency, modular and robust. In order to achieve wide operating speed range magnetic pad design minimizing magnetic coupling deviation is required. Series-series resonant converter will be designed. System will have a speed operating range of 0-3000 rpm hence a FEA model will be built. Resonant converters are usually considered difficult to design however they allow zero voltage/current switching which increases efficiency. The system will be fed from the grid and the overall efficiency is aimed to be >90% under all load and coupling conditions. Silicon Carbide (SiC) will be used as switching unit which have lower switching losses than Si MOSFET/IGBT and higher possible operating temperatures.

At the end of the project the wireless power transfer unit will be capable of delivering 1kW of power. This module will be first designed to be used as a wind turbine slip ring and the prototype will be brought to TRL-6 level. The prototype can be also used in the industrial and military purposes.

Figure 1: (a) Industrial contactless slip ring (b) Proposed modular contactless power transfer slip ring design